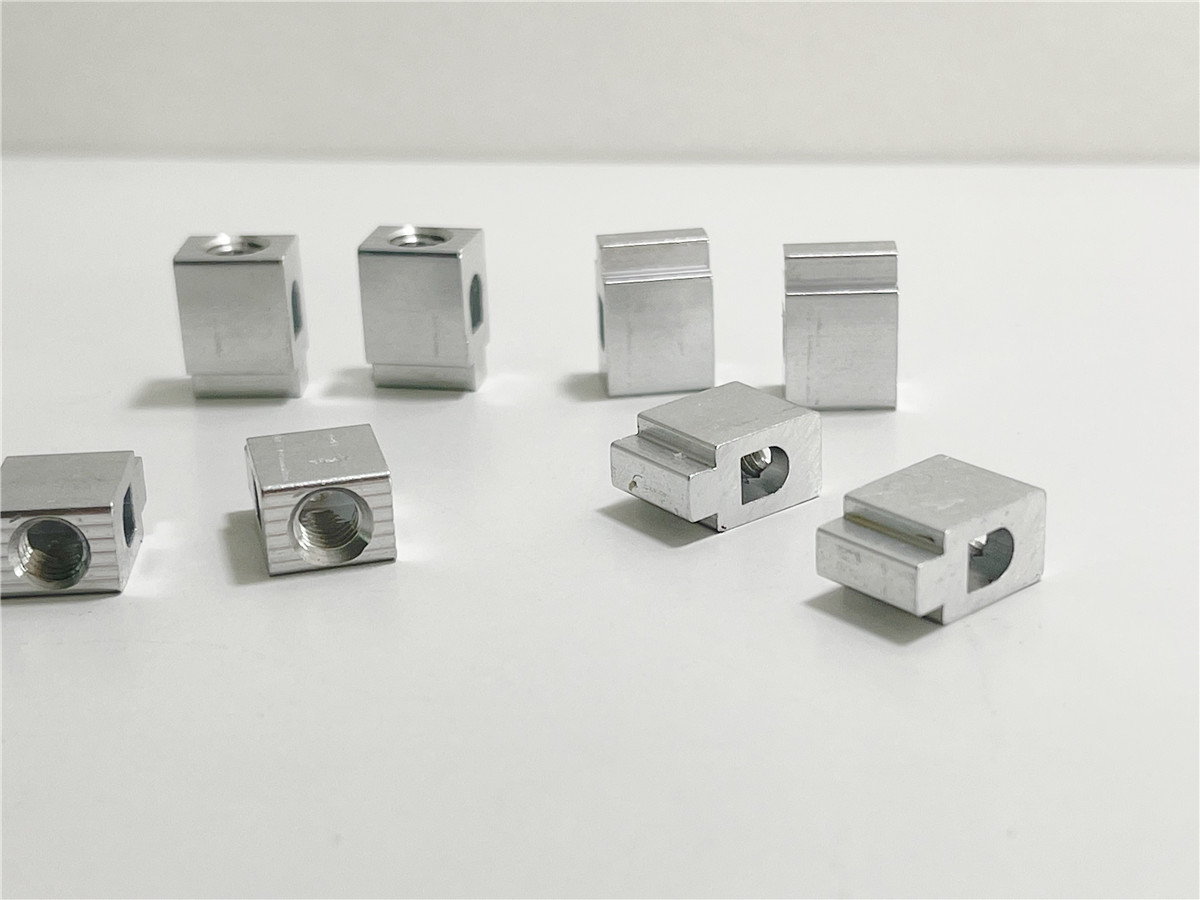

Setulo se Kopantsoeng Sehokelo sa Aluminium se Tsitsitseng sa Lebokose

Mekhahlelo

| CNC Machining kapa Che | Cnc Machining | Mamello | ±0.005-0.01 | ||

| Matla a Lintho | Aluminium, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Tšepe Alloys | Ho paka | Mafome a thibelang mafome a PP/PE Mabokose a mabokose a lepolanka Liphalete | ||

| Mofuta | Broaching, DILLING, Etching / Chemical Machining, Laser Machining, Milling, Litšebeletso tse ling tsa Machining, Ho Fetola, Wire EDM, Rapid Prototyping | Lisebelisoa Tse Fumanehang | Aluminium, koporo, tšepe, tšepe, titanium alloy, POM, ABS, nylon | ||

| Micro Machining kapa Che | Micro Machining | Letšoao | Amohela Letšoao la Tloaelo | ||

| Nomoro ea Mohlala | Aluminium cs113 | Setifikeiti | ISO 9001:2015 | ||

| Lebitso la Brand | OEM | Kopo | Lisebelisoa tsa boiketsetso | ||

| Mofuta oa Ts'ebetso | Milling Turning Machining Casting Stamping | Ho qetela | ho bentša anodizing | ||

| Mohlala | nakong ea matsatsi a 7 | ||||

| Nako ea ho etella pele: Nako ea ho tloha ha odara e behiloe ho isa ho thomello | Bongata (likotoana) | 1-10 | 11-100 | 101-1000 | > 1000 |

| Nako ea ho tsamaisa (matsatsi) | 5 | 7 | 17 | Ho buisanoa | |

Lintlha tsa Sehlahisoa

1. High Precision Metal Likarolo

Sehokelo sa aluminium ke karolo ea tšepe e phahameng ka ho fetesisa, eo hangata e entsoeng ka thepa ea boleng bo holimo ea aluminium le ho nepahala-e entsoeng ke theknoloji ea machining ea CNC. Ts'ebetso ea ho etsa karolo ena e hloka tšebeliso ea lisebelisoa tse tsoetseng pele tsa CNC lathe le theknoloji ea machining e nang le li-multi-axis ho netefatsa ho nepahala le ho tsitsa ha eona.

2. Mosebetsi o ka sehloohong: kopanya likarolo kapa likarolo tse fapaneng

Mosebetsi o ka sehloohong oa karolo ena ke ho hokahanya litho kapa likarolo tse fapaneng le ho li tšoara hammoho. Hangata e na le setulo se kopanyang, molaleng o tsitsitseng, kholomo e tsitsitseng le clamp ea screw. Socket e fana ka sethala seo likarolo tse ling li ka hokeloang ho sona. Mosebetsi oa khola e tsitsitseng le poso e tsitsitseng ke ho netefatsa botsitso le ho tšepahala ha khokahanyo ha u ntse u boloka tekanyo e itseng ea ho ferekana le ho tiisa. Li-clamp tsa screw li sebelisoa ho tiisa sehokelo kaofela ho netefatsa khokahano e tiileng.

3. Melemo ea ts'ebetso ea machining ea CNC

Sehokelo sa aluminium se nang le sleeve e tsitsitseng, selikalikoe, sekoti se tsitsitseng le sehokelo sa aluminium sa clamp se entsoeng ke theknoloji ea ts'ebetso ea CNC se na le melemo e mengata. Pele ho tsohle, ts'ebetso ea machining ea CNC e na le ho nepahala le botsitso bo phahameng, e ka netefatsang ho nepahala le ho tsitsa ha boholo ba karolo. Ka tsela ena, sehokelo se ka ikamahanya hantle le litlhoko tse fapaneng tsa khokahano mme sa netefatsa ho tiea le botsitso ba khokahano.

4. E fana ka khetho ea motho ka mong le tharollo ea ho ntlafatsa

Phetoho le tloaelo ea ho sebetsana le setulo se hokahanyang, sleeve ea ho lokisa, sekontiri se tsitsitseng sa screw clamp aluminium se fa bareki khetho ea motho ka mong le tharollo ea ho ntlafatsa. Bareki ba ka etsa lihokelo tsa boholo bo fapaneng, libopeho le mesebetsi ho latela litlhoko le litlhoko tsa bona. Ka nako e ts'oanang, sehlopha sa rona sa litsebi se tla fana ka tšehetso ea tekheniki le likeletso ho netefatsa liphetho tse ntle ka ho fetisisa moralong le ts'ebetsong ea sehokelo.