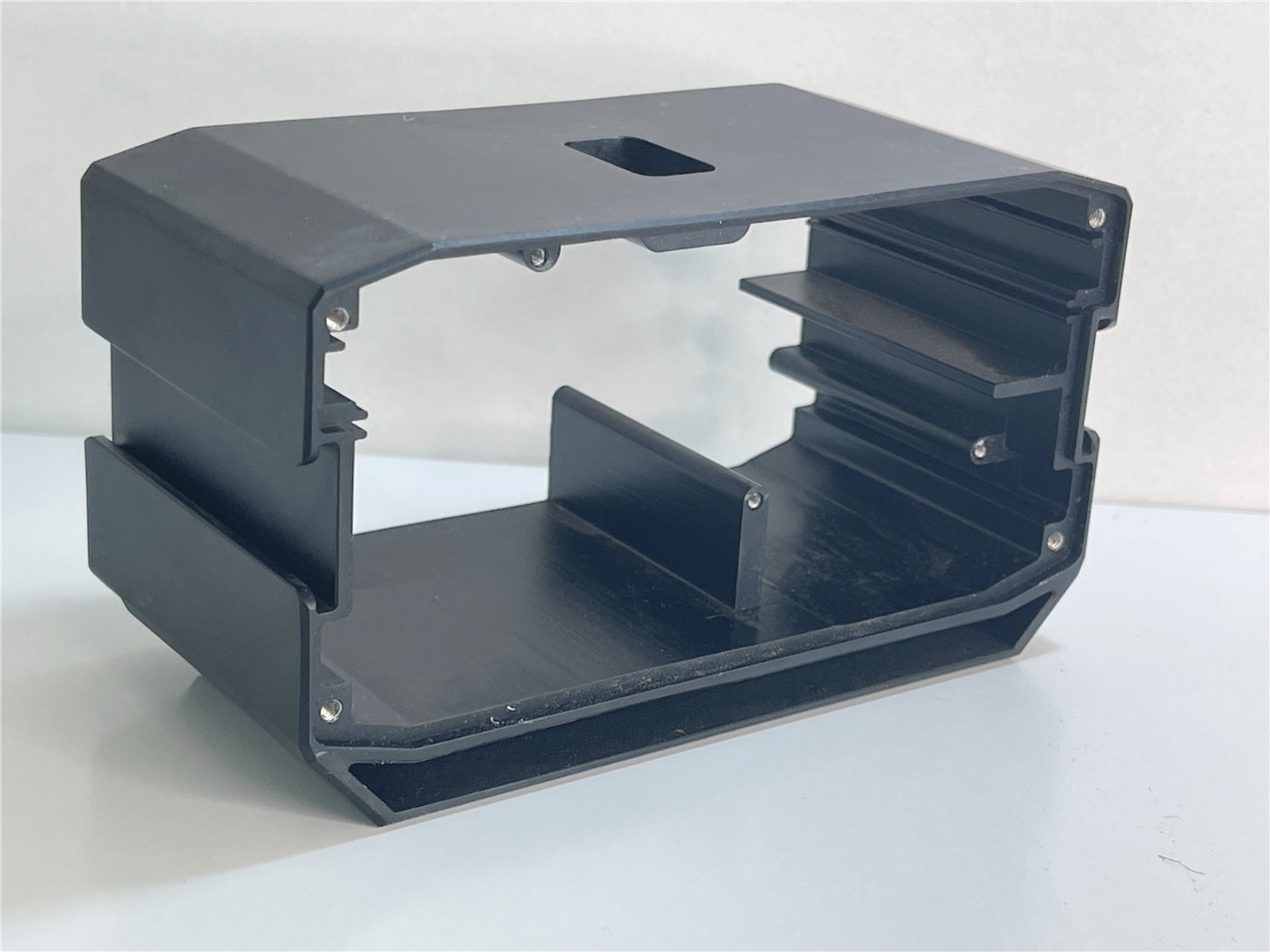

Custom Electroplated Baking Varnish Extrusion Electronic Board Enclosure Parts

Mekhahlelo

| Lebitso la Sehlahiswa | Custom Electroplated baking varnish Extrusion electronic board boto likarolo tse ka hare | ||||

| CNC Machining kapa che: | Cnc Machining | Mofuta: | Broaching, DILLING, Etching / Chemical Machining. | ||

| Micro Machining kapa Che: | Micro Machining | Tsebo ea Lintho: | Aluminium, Brass, Bronze, Copper, Hardened Metals, Precious Stainless stell, Alloys ea tšepe | ||

| Lebitso la Brand: | OEM | Sebaka sa Tšimoloho: | Guangdong, China | ||

| Boitsebiso: | Aluminium 6061 | Nomoro ea Mohlala: | Aluminium cs071 | ||

| Mmala: | Ntsho | Lebitso la Ntho: | Aluminium cs071 likarolo tse koetsoeng ka boto ea elektroniki cnc | ||

| Phekolo ea sefahleho: | Ho penta | Boholo: | 3 limilimithara - 10 limilimithara | ||

| Setifikeiti: | IS09001:2015 | Lisebelisoa Tse Fumanehang: | Aluminium Stainless Plastic Metals Copper | ||

| Ho paka: | Poly Bag + Inner Box + Carton | OEM/ODM: | E amohetsoe | ||

| Mofuta oa Ts'ebetso: | Setsi sa Ts'ebetso sa CNC | ||||

| Nako ea ho etella pele: Nako ea ho tloha ha odara e behiloe ho isa ho thomello | Bongata(likotoana) | 1-1 | 2 - 100 | 101 - 1000 | > 1000 |

| Nako ea ho tsamaisa (matsatsi) | 5 | 7 | 7 | Ho buisanoa | |

Melemo

Mekhoa e Mengata ea Ts'ebetso

● Ho phunya, ho Epa

● Etching/ Chemical Machining

● Ho phethola, WireEDM

● Ho Ngola ka Potlako

Ho nepahala

● Ho sebelisa thepa e tsoetseng pele

● Ho laola boleng ka thata

● Sehlopha sa litsebi tsa theknoloji

Molemo oa Boleng

● Product Support traceability ea lihlahisoa tse tala

● Taolo ea boleng e etsoang meleng eohle ea tlhahiso

● Ho hlahloba lihlahisoa tsohle

● R&D e matla le sehlopha sa tlhahlobo ea boleng ba litsebi

Lintlha tsa Sehlahisoa

Karolo ena ea electroplated pente extrusion electronic board enclosure ke karolo ea tšepe ea CNC e nang le seaparo se sefubelu sa holim'a metsi, mosebetsi oa eona ke ho fana ka tšireletso e tiileng le ponahalo e ntle ea lisebelisoa tsa elektronike. Mona ke tlhaloso e qaqileng ea sehlahisoa:

1. Ho sebelisa lisebelisoa tsa tšepe tsa boleng bo phahameng

Likarolo tsa casing li entsoe ka lisebelisoa tsa tšepe tsa boleng bo holimo 'me li etsoa ka mokhoa oa extrusion. Sena se fa likarolo tsa casing matla a matla a mochini le nako e telele, e li nolofalletsang ho mamella khatello le tšusumetso e tsoang libakeng tse fapaneng le ho sireletsa boto ea elektronike e ka hare ho tšenyo.

2. E sebetsoa ka electroplating le ho baka pente

Likarolo tsa casing li etsoa kalafo ea electroplating le ho baka ho penta, ho li fa seaparo se setšo sa bokaholimo. Ho roala hona ha ho ntlafatse ponahalo ea sehlahisoa feela empa hape ho fana ka khanyetso ea kutu le ho hanyetsa ho apara. Ka ho roala ka holim'a metsi, likarolo tsa casing li ka hanela ka katleho lintho tse kang mongobo, oxidation, le mengoapo tikolohong e kantle, ka hona, li lelefatsa bophelo bohle ba sesebelisoa sa elektroniki.

3. E entsoe ka theknoloji ea ho sebetsa ka tšepe ea CNC

Likarolo tsa casing li etsoa ho sebelisoa theknoloji ea ts'ebetso ea tšepe ea CNC. Theknoloji ea ts'ebetso ea tšepe ea CNC e na le ho nepahala ho phahameng le ho iketsetsa, ho netefatsa ho nepahala le ho tsitsisa ha likarolo tsa casing. Mokhoa ona oa tlhahiso ha o ntlafatse ts'ebetso ea tlhahiso feela empa hape o tiisa botsitso le ho tšepahala ha lihlahisoa. Ha u sebelisa likarolo tsena tsa casing, ho hlokahala hore u khethe pele mohlala o nepahetseng oa casing ho latela litekanyo le litlhoko tsa sesebelisoa sa elektronike. Joale, likarolo tsa casing li lokela ho kenngoa hantle holim'a boto ea potoloho, ho netefatsa hore ho na le khokahanyo e sireletsehileng le likarolo tse ling. Ka mehato e nepahetseng ea ho lokisa le ho kenya, likarolo tsa casing li ka koala ka ho feletseng le ho sireletsa boto ea potoloho ha li ntse li boloka ponahalo ea kakaretso ea sesebelisoa.

Ho akaretsa, karolo ena ea pente ea electroplating extrusion e kampetsoeng ea boto ea elektronike ke karolo ea tšepe ea CNC e nang le letlalo le letšo, le entsoeng ka lisebelisoa tsa tšepe tsa boleng bo phahameng, tse ka fanang ka tšireletso e tiileng le ponahalo e ntle. Ka kalafo ea pente ea ho baka ea electroplating le theknoloji ea ts'ebetso ea tšepe ea CNC, e na le litšobotsi tsa anti-corrosion, e sa senyeheng le e nepahetseng. Ka ho kenya le ts'ebeliso e nepahetseng, karolo ea matlo e ka sireletsa lisebelisoa tsa elektronike ka katleho le ho ntlafatsa boleng le ponahalo ea sehlahisoa ka kakaretso.